In the industrial world manufacturers and engineers constantly seek solutions to improve efficiency, reduce energy costs and extend equipment life. One emerging technology gaining attention is Tribupneu.

By combining principles from tribology and pneumatic technology offers a smarter approach to managing air powered machines. Its importance is rising now as industries adopt automation robotics and sustainability focused production methods.

Understanding Pneumatic technology helps businesses modernize their operations without extensive overhauls. This article explains its core concepts benefits real world applications and future potential providing a complete guide for professionals engineers and decision makers.

What Is Tribupneu?

Air powered motion systems is a specialized technology that merges two fields: tribology the science of friction wear and lubrication and pneumatics which involves using pressurized air for motion.

By combining these disciplines Friction control systems reduce friction between moving parts while maintaining smooth and efficient motion in air powered devices. At its core Friction control systems focus on controlling airflow adjusting pressure as needed and providing consistent performance.

Unlike traditional pneumatic systems it actively manages the interaction between air machine components and sensor feedback to improve reliability and operational precision. The technology is adaptable across multiple home industrial sectors making it relevant for modern manufacturing.

How Tribupneu Works?

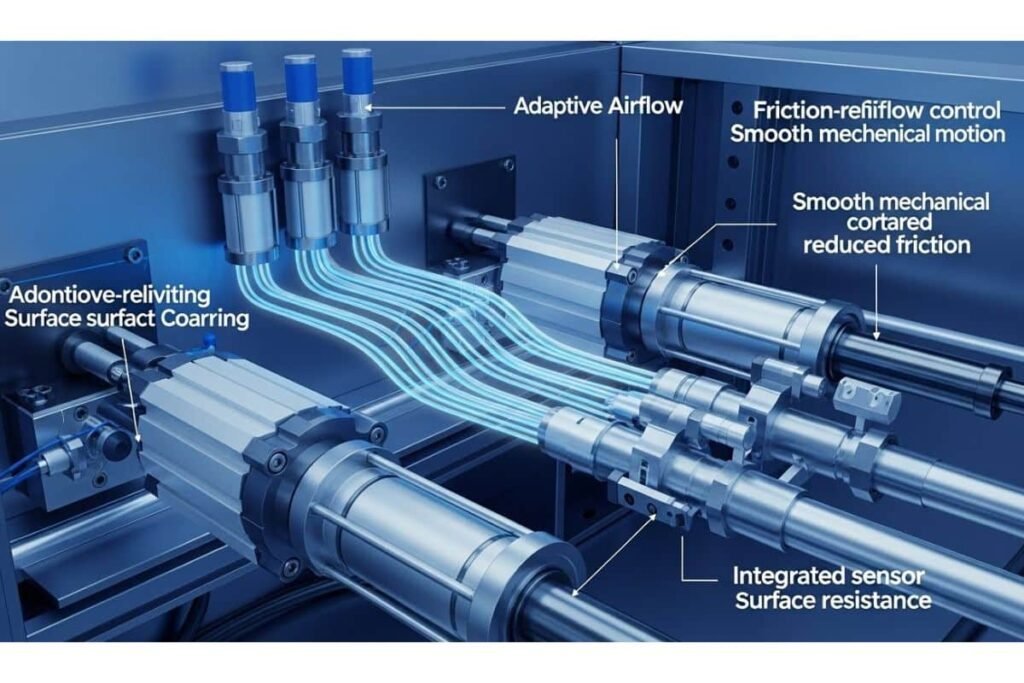

Air powered motion systems work by carefully managing how air moves through machinery while reducing friction on critical components. It uses advanced materials, coatings and designs to create a protective barrier on moving surfaces.

This barrier minimizes direct contact prevents wear and allows machines to operate smoothly for longer periods.Integrated sensors monitor pressure and surface resistance continuously. When friction or air resistance changes the system automatically adjusts airflow or lubrication.

This adaptive response keeps performance consistent and helps machines maintain their efficiency even under varying workloads. By combining these mechanisms air powered motion systems enhance both energy efficiency and mechanical reliability.

Friction Reduction and Surface Protection

A primary function of Pneumatic technology is to minimize friction. High friction in traditional pneumatic systems causes energy loss wear on components and inconsistent machine performance.

Pneumatic technology addresses this with advanced tribological coatings and synthetic lubricants. These treatments form microscopic layers that prevent metal to metal contact, reduce wear on cylinders, valves and actuators and extend equipment life.

Smart Airflow Control and Sensor Feedback

Tribology based pneumatics systems include sophisticated airflow management. Sensors constantly measure pressure temperature and lubrication levels. The system uses this data to adjust air distribution in real time.

This control ensures that machines operate efficiently with minimal turbulence reducing energy loss and improving the predictability of automated processes.

Materials and Durability

Specialized polymers nano lubricants and self healing coatings are central to Tribology based pneumatics. These materials handle high loads, temperature fluctuations and continuous motion without breaking down.

Components like seals, cylinders and valves maintain their performance longer than those in standard systems reducing downtime and maintenance requirements.

Benefits of Tribupneu

The advantages of Energy efficient pneumatic systems are notable across several industrial dimensions. Companies adopting this technology often see improvements in energy efficiency machine longevity maintenance planning and operational stability.

Energy efficiency improves because reduced friction means less power is needed for pneumatic actuation. Machines operate with less wasted energy and compressors work less frequently reducing electricity costs.

Durability increases as components experience less wear and require fewer replacements. Predictable machine performance supports smoother workflows especially in automated production lines.

Energy efficient pneumatic systems also contribute to sustainability goals. By optimizing air consumption and reducing unnecessary energy use industries can lower their carbon footprint while maintaining high productivity.

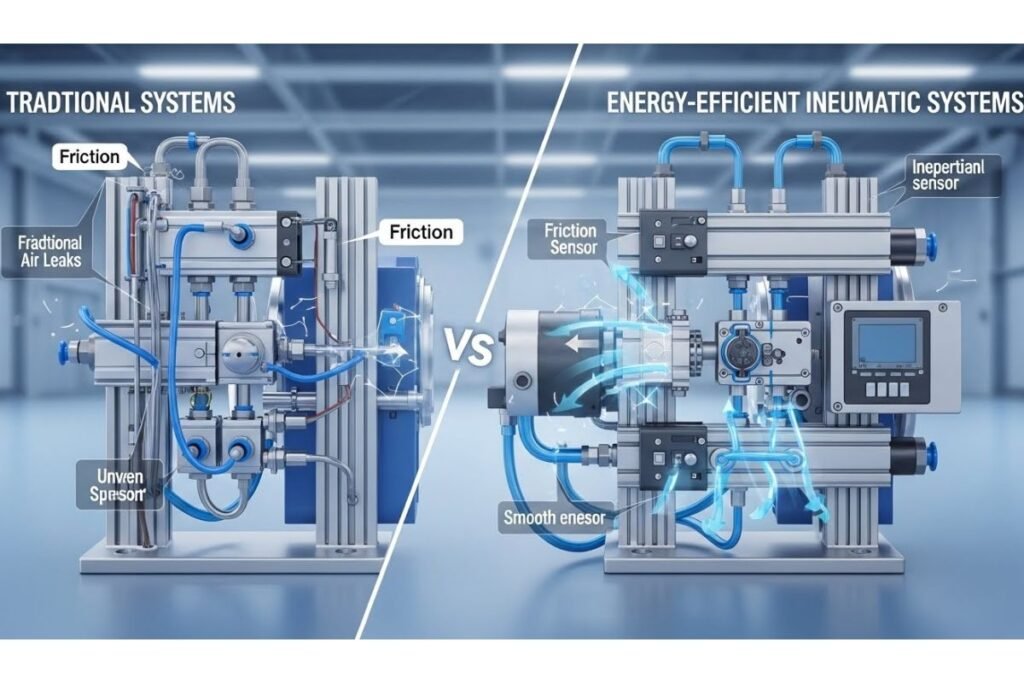

Tribupneu Compared to Traditional Pneumatic Systems

Traditional pneumatic systems rely on air pressure to drive mechanical motion but often suffer from inefficiencies. Air leaks inconsistent pressure and friction reduce performance and increase energy consumption.

In contrast, Energy efficient pneumatic systems use tribological principles to control friction while integrating sensors for real time adjustments. This results in smoother motion, better precision and longer lasting components.

Unlike hydraulic systems that depend on oil based fluids Industrial automation pneumatic solutions use clean air minimizing contamination risks and environmental impact.

Its energy efficient design ensures machines run optimally without excessive power demands making it an attractive option for modern industrial setups.

Applications of Tribupneu Technology

Tribupneu’s versatility allows it to be applied across various industries from manufacturing to robotics. In automated production lines it improves assembly accuracy and reduces downtime by maintaining consistent air pressure.

In robotics it enables smoother more precise movements which is crucial for handling delicate materials or performing repetitive tasks.Packaging systems conveyor belts and material handling machines also benefit.

The technology ensures steady operation lowers energy consumption and reduces maintenance requirements. Emerging applications in aerospace and medical devices highlight its potential in high precision fields where reliable pneumatic control is essential.

Industrial Automation

Automated factories use Industrial automation pneumatic solutions to enhance production speed and reliability. The system’s ability to adapt to changing loads and conditions allows continuous operation with minimal intervention.

Predictive maintenance supported by sensor feedback reduces unexpected breakdowns keeping assembly lines moving efficiently.

Robotics Applications

In robotics Industrial automation pneumatic solutions facilitate precise motion control. Robots equipped with this technology move more naturally, reducing jerky actions and extending the life of mechanical components.

Energy savings are also significant as reduced friction lowers power demands on actuators and compressors.

Emerging Industrial Uses

New research explores Sensor driven air systems in experimental energy systems and smart materials. While these applications are still developing, the potential for adaptive self regulating systems in industrial machinery is promising. Such innovations could set the standard for the next generation of pneumatic technology.

Case Studies and Performance Metrics

Companies implementing Sensor driven air systems often report measurable improvements. Factories see reductions in energy consumption by optimizing airflow and reducing friction.

Equipment lifespan increases due to lower wear rates and maintenance intervals extend because components degrade more slowly. These gains result in cost savings and more stable production output.

Although specific data varies by sector the overall trend demonstrates that Sensor driven air systems enhance operational efficiency, reliability and sustainability.

Conclusion

Tribupneu represents a meaningful advancement in pneumatic technology. By combining friction control airflow optimization and sensor driven feedback it delivers smoother motion higher energy efficiency and longer lasting machinery.

As industries embrace automation and sustainability Pneumatic technology offers a practical adaptable solution for modern manufacturing and robotics.

Understanding and applying this technology can help businesses improve operations while reducing costs and environmental impact.

FAQS

How does Tribology based pneumatics impact maintenance schedules?

Tribology based pneumatic systems reduce wear on components allowing maintenance to be planned around actual usage rather than fixed intervals. This predictive approach helps factories avoid unexpected downtime and lower maintenance costs.

Can Tribupneu technology be integrated into existing machinery?

Yes. Air powered motion systems and friction control systems can often be retrofitted into existing pneumatic setups. Integration depends on component compatibility and airflow requirements allowing manufacturers to upgrade without replacing entire systems.

Does Tribupneu improve workplace safety?

Energy efficient pneumatic systems and sensor driven air systems provide smoother quieter operation. This reduces sudden jerks, mechanical failures and excessive noise which can enhance safety in industrial and manufacturing environments.

What role do sensors play in Tribology based pneumatics?

Sensors continuously monitor pressure friction and airflow. This data enables adaptive responses in real time ensuring optimal performance preventing component wear and supporting predictive maintenance strategies.

How energy efficient are air powered motion systems compared to traditional pneumatics?

Tribology enhanced pneumatic systems reduce friction and air turbulence resulting in lower power consumption for actuators and compressors. This leads to measurable energy savings over time especially in automated and high cycle industrial operations.

Which industries can benefit most from friction control systems?

Industrial automation robotics packaging aerospace and medical device manufacturing gain the most. Any sector requiring precise air powered motion, low energy consumption and reliable performance can benefit from these systems.